Contacts and Location

| Enquire about this equipment | |

| Organisational Unit |

Riga Technical University Faculty of Civil Engineering Institute of Materials and Structures - Latvia, Rīga |

| Building | Rīga, Ķīpsalas, 6A |

Description

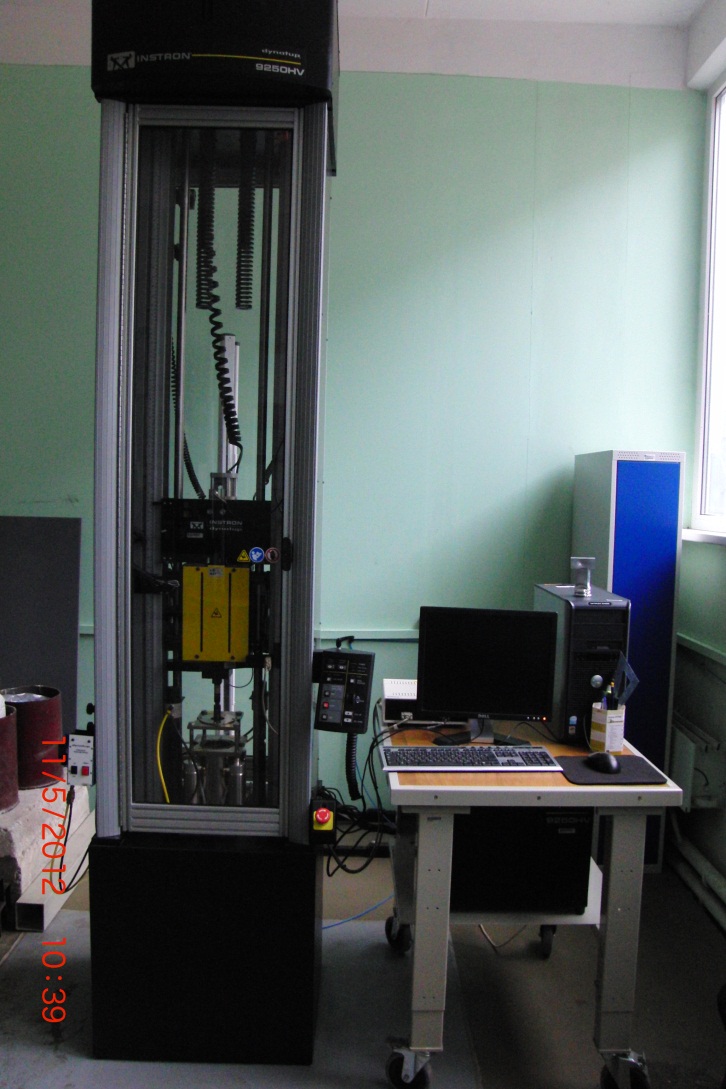

Servohydraulic fatigue testing system which is designed for static and dynamic loading with the opportunity to put a constant, growing or changing load (cycling) in tension, compression or bending. Static and dynamic material properties can be determined for materials such as: metals, plastics, fabrics, wood, composite materials. Load range is 250 kN. The machine is equipped with Dynacell type load cell which includes machine components, inertia compensation mechanisms. Machine components are fatigue resistant, thus, it is particularly suitable material fatigue testing. Accuracy class according to ASTM E74 Class A/A1 standard.

Specification

main function:

parameters:

Services

static and dynamic determination of different materials as plastics, fabrics, wood, composite materials with a constant, growing or changing load (cycling) in tension, compression or bending

Status

Manufacturer

Instron

Model

8802