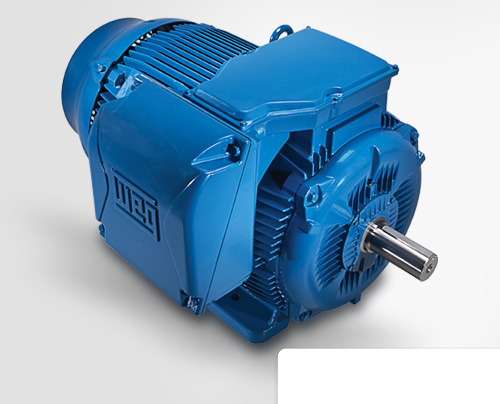

W22: • Excellent cost benefit ratio • Optimization of energy resources • Updated electrical features • Noise level reduction • Vibration level reduction • Easier maintenance • Improving efficiency levels High performance with maximum energy efficiency, this is the meaning of the new WEG electric motor. High efficiency and Low cost of Ownership throughout the entire motor lifetime have been the basis for the W22 development. A design created to anticipate concepts on performance and energy savings.

Characteristics

- Frame: 63

- Output: 0.09 kW

- Frequency: 60 Hz

- Poles: 4

- Full load speed: 1725

- Slip: 4.17 %

- Voltage: 230/400 V

- Rated current: 0.673/0.387 A

- Locked rotor current: 3.50/2.01 A

- Locked rotor current (Il/In): 5.2

- No load current: 0.526/0.303 A

- Full load torque: 0.499 Nm

- Locked rotor torque: 320 %

- Breakdown torque: 340 %

- Design: N

- Insulation class: F

- Temperature rise: 80 K

- Locked rotor time: 22 s (hot)

- Service Factor: 1.15

- Duty cycle: S1

- Ambient temperature: -20°C – +40°C

- Altitude: 1000 m

- Degree of Protection: IP55

- Approximate weight: 7 kg

- Moment of inertia: 0.00033 kgm²

- Noise level: 48 dB(A)

Standard Features

- Three-phase, multivoltage, IP55, TEFC;

- Standard efficiency - complying with IE1 efficiency levels according to IEC60034-30;

- Output: 0,12 up to 500kW;

- Number of Poles: 2, 4, 6 and 8;

- Frames: 63 up to 355A/B;

- Mounting: B3T;

- Voltage: 220-240/380-415V / 380-415/660V;

- Class “F” insulation (ΔT=80K);

- Continuous duty: S1;

- Design N;

- WISE® (WEG Insulation System Evolution) insulation system - Suitable for inverter duty applications*;

- Thermistors (1 per phase) for frames 160M to 355A/B;

- Ambient temperature: 40°C, at 1000 m.a.s.l.;

- Squirrel cage rotor / Aluminium die cast;

- V'Ring seal for frames 63 to 200L and for frames 225S/M to 355A/B;

- Stainless steel nameplate AISI 316;

- Fan Covers: steel made for frames 63 to 132M/L and cast iron made for frames 160M to 355A/B;

- Regreasing nipple for frames 225S/M to 355A/B;

Optional Available

- Frequency: 60 Hz;

- Other voltages;

- Design H;

- Class “H” insulation;

- Thermostats or RTD-PT 100 on winings and bearings;

Thermal protection:

- Degree of Protection: IP56, IP65, IP66, IPW56, IPW65 or IPW66;

- Bearing seals:

- Lip seal ;

- Oil seal ;

- Labyrinth taconite seal and W3seal;

- Additional terminal box;

- Space heaters;

- Fans: Aluminum, Cast Iron and

- Drip cover for vertical applications;

- Double shaft end;

- Encoder;

- Cable glands in plastic and brass;

- Blower kit (TEBC);

- Roller bearings;

Typical Applications: Pumps; Fans; Crushers; Conveyor belts; Mills; Centrifugal; Presses; Elevators; Packaging equipment; Grinders and others.

free